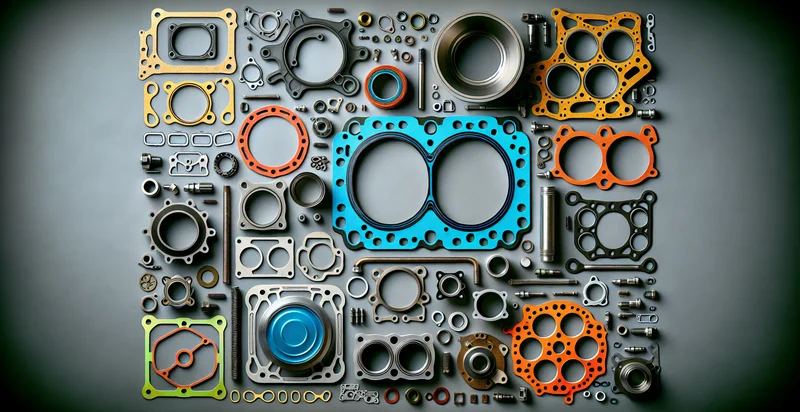

Identify gasket integrity

using AI

Below is a free classifier to identify gasket integrity. Just upload your image, and our AI will predict if the gasket is intact - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("gasket-integrity", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/gasket-integrity/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/gasket-integrity/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the gasket is intact.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Leaking and Sealed.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the gasket is intact).

Whether you're just curious or building gasket integrity detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify gasket integrity at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

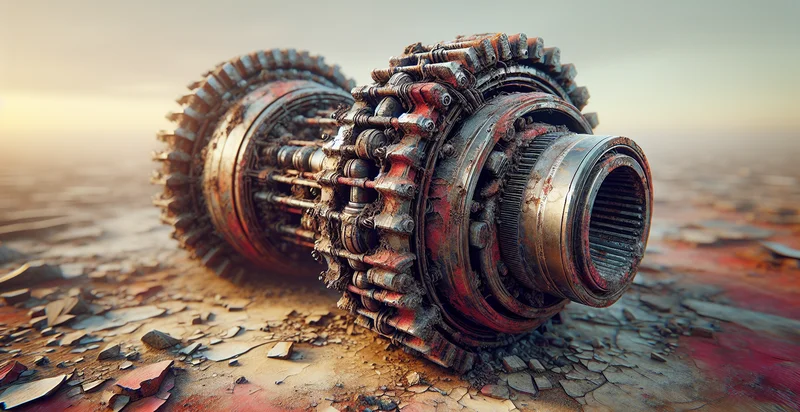

- Preventive Maintenance: By utilizing the gasket integrity identifier, manufacturers can proactively monitor the condition of gaskets in equipment. This enables them to schedule maintenance before failures occur, reducing downtime and maintenance costs.

- Quality Control: In production environments, the gasket integrity identifier can be integrated into quality control processes. This ensures that only gaskets meeting required specifications are used, minimizing the risk of leaks and enhancing product reliability.

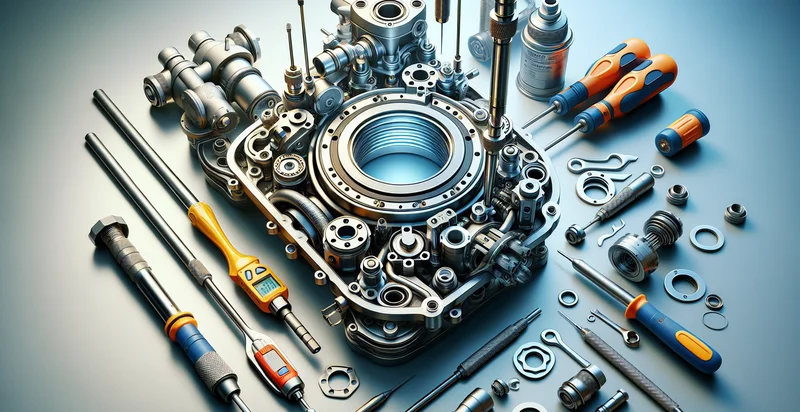

- Field Inspection Automation: Service technicians can leverage the gasket integrity identifier in the field to quickly assess the condition of gaskets in various machines. This speeds up inspection times and improves the accuracy of condition assessments, allowing for timely interventions.

- Supply Chain Optimization: Companies can use gasket integrity data to inform their procurement strategies. By identifying which gasket designs perform well and last longer, businesses can optimize their inventory choices and reduce waste related to failed components.

- Regulatory Compliance: Industries such as oil and gas can utilize the gasket integrity identifier to ensure compliance with safety regulations. By documenting gasket conditions, companies can demonstrate adherence to industry standards and avoid costly fines.

- Customer Support Enhancement: Customer service teams can use the gasket integrity identifier to assist clients experiencing issues with equipment. By accurately diagnosing gasket failures remotely, support personnel can provide targeted recommendations, enhancing customer satisfaction.

- Training and Development: The gasket integrity identifier can be used as a training tool for new employees in maintenance and inspection roles. By familiarizing staff with accurate identification techniques, organizations can improve overall workforce competence and reduce error rates.