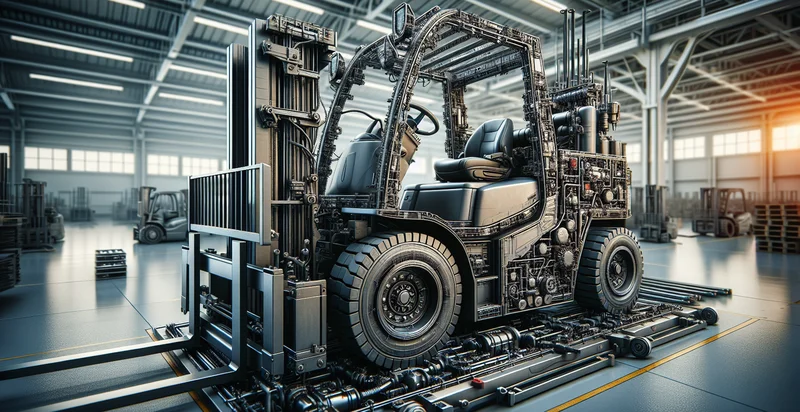

Identify forklift conditions

using AI

Below is a free classifier to identify forklift conditions. Just upload your image, and our AI will predict the operational state of the forklift under various conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("forklift-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/forklift-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/forklift-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational state of the forklift under various conditions.

This pretrained image model uses a Nyckel-created dataset and has 6 labels, including Excellent Condition, Fair Condition, Good Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational state of the forklift under various conditions).

Whether you're just curious or building forklift conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify forklift conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Maintenance Prediction: The forklift conditions identifier can monitor the machinery's operational state to predict maintenance needs. By analyzing images for signs of wear and tear, it helps prevent breakdowns, reducing unplanned downtime and maintenance costs.

- Safety Compliance: This function can help ensure that forklifts are in safe operating conditions by identifying any visible safety violations or equipment hazards. Regularly capturing and analyzing images of forklifts allows companies to maintain compliance with safety regulations, ultimately protecting employees and reducing liability.

- Operational Efficiency Analysis: By evaluating the conditions of forklifts in operation, this tool can provide insights into usage patterns and efficiency metrics. Businesses can analyze trends in equipment conditions to optimize operations and increase overall productivity.

- Asset Management: The forklift conditions identifier can assist in tracking the condition of multiple units in a fleet. By cataloging the visual state of each forklift, it supports informed decisions about asset replacement or upgrades based on actual usage condition rather than just age.

- Training and Quality Control: This function can be utilized in training programs for new operators by providing a visual reference of ideal conditions versus faulty equipment. It helps in establishing quality control standards, ensuring operators understand what to look for when assessing forklift conditions.

- Insurance Verification: Insurance companies can use this technology to assess forklift conditions for evaluating claims or setting premiums. An automated system can provide evidence-based evaluations of machinery that helps support claims and reduces fraud risks.

- Historical Condition Tracking: The identifier can help maintain a historical record of forklift conditions over time. This data can be leveraged for long-term investment strategies, sustainability practices, or corporate responsibility reporting by tracking trends related to equipment lifecycle and reliability.