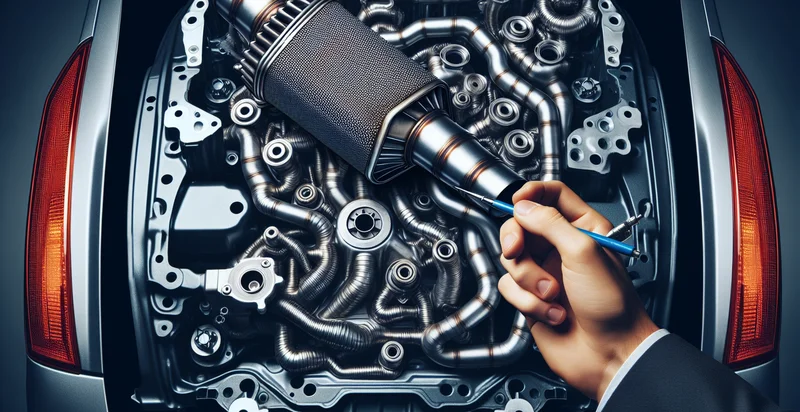

Identify exhaust layout

using AI

Below is a free classifier to identify exhaust layout. Just upload your image, and our AI will predict the layout of exhaust systems in various vehicle models. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("exhaust-layout", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/exhaust-layout/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/exhaust-layout/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the layout of exhaust systems in various vehicle models..

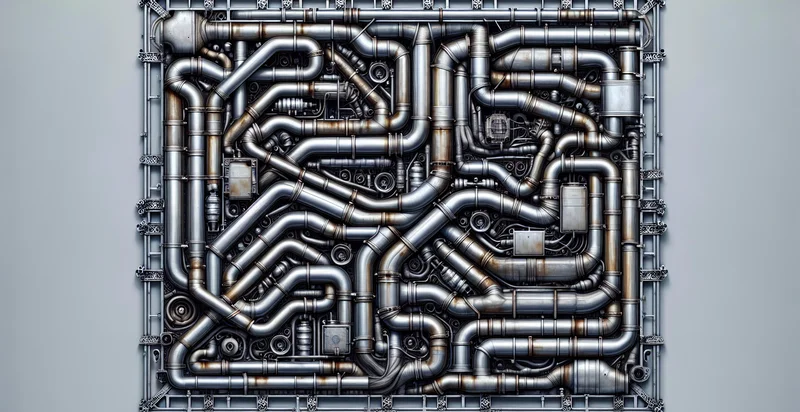

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Dual, Eight, Five, Nine, Quad, Seven, Single, Six, Ten and Triple.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the layout of exhaust systems in various vehicle models.).

Whether you're just curious or building exhaust layout detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify exhaust layout at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: The exhaust layout identifier can be used in manufacturing facilities to automatically detect and classify defects in exhaust systems during assembly. By integrating this function into quality assurance processes, companies can minimize errors, ensure compliance with design specifications, and enhance overall product reliability.

- Automotive Design Validation: Automotive engineers can employ the exhaust layout identifier to validate exhaust system designs against existing standards. This allows for early detection of design discrepancies, potentially saving time and resources during the prototyping phase and ensuring that final products meet regulatory requirements.

- Automated Inspection Systems: In automotive workshops, the exhaust layout identifier can be integrated into automated inspection systems that quickly assess installed exhaust components. This speeds up the service process and allows technicians to focus on more complex repairs while ensuring accurate and consistent evaluations of exhaust layouts.

- Compliance Monitoring for Emission Standards: Regulatory agencies can utilize the exhaust layout identifier to monitor compliance with emission standards in vehicles. By systematically identifying incorrect exhaust layouts, agencies can enforce regulations more effectively and improve overall air quality.

- Supply Chain Management: Manufacturers can leverage the exhaust layout identifier to ensure that suppliers provide compliant exhaust layouts before parts are assembled into final products. This reduces the risk of costly recalls and enhances the reliability of the supply chain by ensuring component quality at the source.

- Data Analytics for Design Improvement: The exhaust layout identifier can be integrated into data analytics systems to gather insights on common design flaws across various exhaust systems. This data can inform future engineering decisions, leading to improvements in design practices and enhanced vehicle performance.

- Training and Development: Educational programs in automotive technology can employ the exhaust layout identifier as a training tool for students and professionals. By visualizing and understanding various exhaust layouts and their classifications, learners can better grasp real-world applications and improve their technical skills.