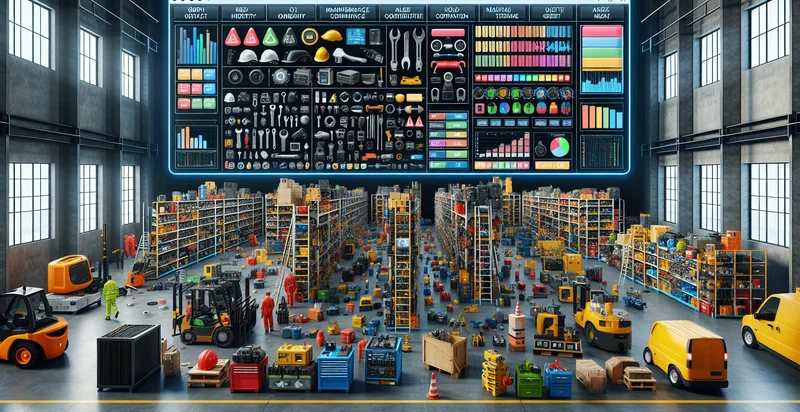

Identify equipment maintenance condition

using AI

Below is a free classifier to identify equipment maintenance condition. Just upload your image, and our AI will predict the maintenance condition of various equipment types - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("equipment-maintenance-condition", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/equipment-maintenance-condition/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/equipment-maintenance-condition/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the maintenance condition of various equipment types.

This pretrained image model uses a Nyckel-created dataset and has 15 labels, including Acceptable Condition, Critical Condition, Deteriorated, Excellent, Fair, Functional, Good, Marginal Condition, Needs Repair and Optimal Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the maintenance condition of various equipment types).

Whether you're just curious or building equipment maintenance condition detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify equipment maintenance condition at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance Alerts: The 'equipment maintenance condition' identifier can analyze sensor data from machinery to predict potential failures before they occur. This proactive approach allows businesses to schedule maintenance only when necessary, reducing downtime and operational costs.

- Inventory Management Optimization: By classifying the maintenance condition of various equipment, companies can adjust inventory levels for spare parts accordingly. This ensures that critical components are readily available without overstocking, leading to more efficient use of resources.

- Enhanced Safety Compliance: By identifying equipment that may require immediate maintenance due to poor operational condition, businesses can ensure better adherence to safety regulations. This reduces workplace accidents attributed to equipment failures, promoting a safer environment for employees.

- Performance Benchmarking: The function can help companies benchmark the performance condition of their equipment against industry standards. Using this data, organizations can make informed decisions on future purchases or upgrades, ensuring they stay competitive in their market.

- Cost Analysis and Reporting: The function generates data insights that can be utilized for detailed cost analysis of maintenance operations. By understanding maintenance patterns and costs associated with equipment, managers can better allocate budgets and resources.

- Training and Development: The insights from the equipment maintenance condition identifier can be used to train personnel on the importance of regular maintenance and condition monitoring. This knowledge transfer can enhance the skill set of staff members, ultimately leading to improved equipment handling.

- Remote Monitoring Solutions: Integrating the condition identifier with IoT technologies can pave the way for remote monitoring of equipment. Businesses can keep track of maintenance conditions in real-time, allowing them to respond swiftly to emerging issues, especially in remote or hard-to-access locations.