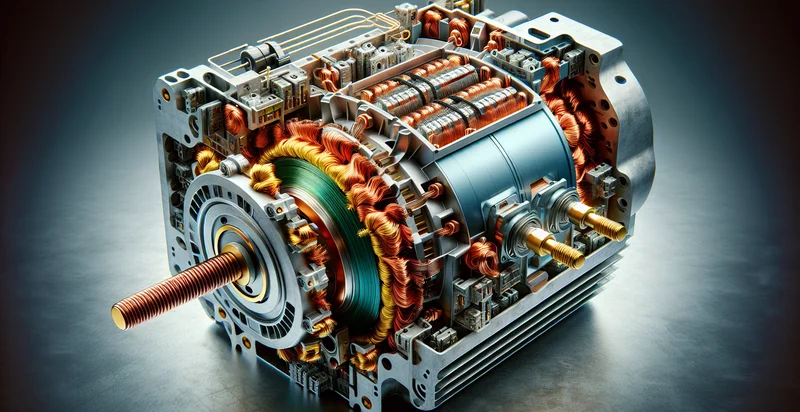

Identify electric motor conditions

using AI

Below is a free classifier to identify electric motor conditions. Just upload your image, and our AI will predict the operational condition of the electric motor - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("electric-motor-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/electric-motor-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/electric-motor-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational condition of the electric motor.

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Excellent Condition, Failed, Fair Condition, Good Condition, Needs Maintenance, Not Operational, Operational and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational condition of the electric motor).

Whether you're just curious or building electric motor conditions detection into your application, we hope our classifier proves helpful.

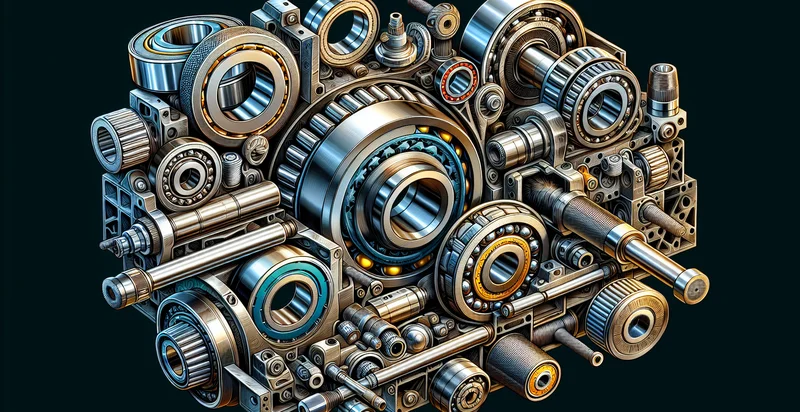

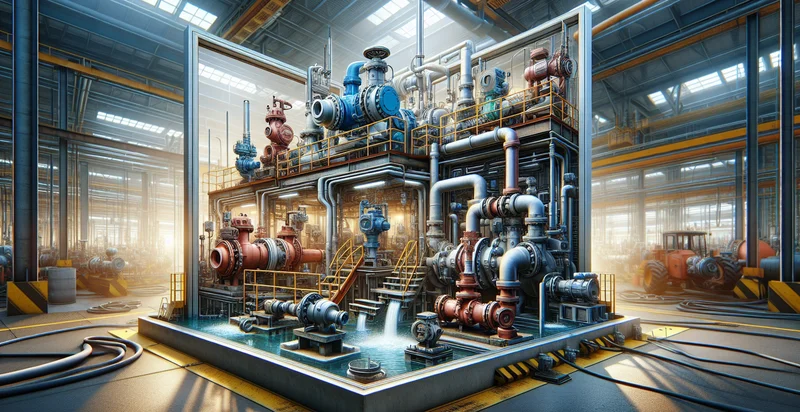

Related Classifiers

Need to identify electric motor conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: This use case involves using the false image classification function to identify abnormal conditions in electric motors before they lead to failure. By continuously monitoring motor conditions, maintenance can be proactively scheduled, reducing downtime and repair costs.

- Quality Control in Manufacturing: The function can be integrated into the production line to assess the quality of electric motors. By classifying images of the motors and identifying any faults, manufacturers can ensure that only defect-free products are shipped to customers.

- Remote Monitoring: This use case leverages the classification function for remote monitoring of electric motors in various industries. Users can receive alerts regarding emerging issues and take corrective actions without the need for physical inspections.

- Training and Development: The classification function can be employed as a part of training programs for technicians and engineers. By providing a database of classified images, learners can better understand typical and atypical motor conditions, enhancing their diagnostic skills.

- Warranty Assessment: In the context of warranty claims, the function can be used to assess the condition of electric motors returned by customers. By accurately classifying the motor conditions, manufacturers can determine the validity of claims and reduce fraudulent requests.

- Performance Analytics: The classification function can analyze historical images of electric motors to identify patterns related to performance degradation. This data can inform product improvements and guide research and development efforts to enhance motor designs.

- Safety Compliance: Using the image classification function can help ensure that electric motors comply with safety standards. By identifying unsafe conditions, organizations can mitigate risks and ensure a safer working environment for operators and maintenance personnel.