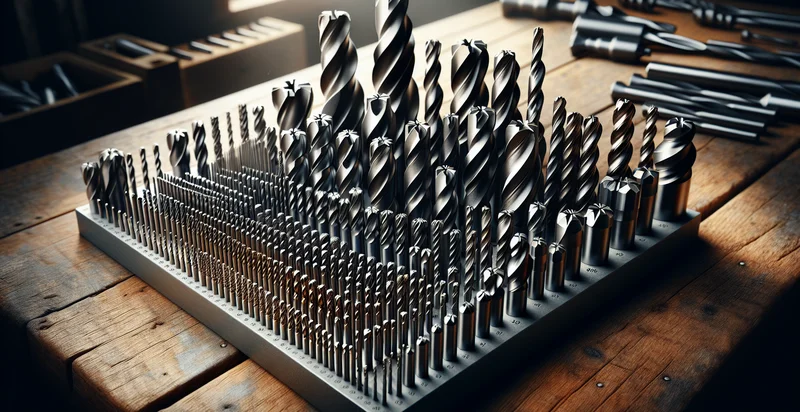

Identify drill bit size

using AI

Below is a free classifier to identify drill bit size. Just upload your image, and our AI will predict what size drill bit is needed - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("drill-bit-size", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/drill-bit-size/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/drill-bit-size/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what size drill bit is needed.

This pretrained image model uses a Nyckel-created dataset and has 5 labels, including Extra Large, Extra Small, Large, Medium and Small.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what size drill bit is needed).

Whether you're just curious or building drill bit size detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify drill bit size at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Automated Inventory Management: The false image classification function can assist businesses in automatically identifying and categorizing drill bit sizes from images, streamlining inventory management. This helps reduce human error in inventory records and ensures that the right sizes are stocked.

- E-commerce Product Matching: Online retailers can integrate the drill bit size identifier to improve the accuracy of product recommendations. By analyzing uploaded user images of drill bits, the system can match them with the correct product listings, enhancing the shopping experience.

- Quality Control for Manufacturing: Manufacturers can utilize the image classification function to evaluate the consistency of drill bit sizes produced in their facilities. This can lead to improved quality assurance processes, minimizing defects and production downtimes caused by mismatched sizes.

- Augmented Reality Tools: Construction and DIY application developers can implement this functionality to create augmented reality tools that help users select the correct drill bit size while working. By using the camera, users could receive real-time recommendations, improving project efficiency and effectiveness.

- Training and Support for Technicians: Organizations can develop training platforms that use the function to enhance the understanding of drill bit sizes for technicians and apprentices. This tool can provide instant feedback on visual identification skills, making training more interactive and effective.

- Equipment Rental Services: Equipment rental businesses can utilize the false image classification to assess and label drill bit sizes as images of the tools are uploaded. This can facilitate easy inventory tracking, reduce miscommunication with clients, and ensure that the correct tools are provided for specific jobs.

- Market Research and Analysis: Businesses can leverage the image classification function to gather data on dissected drill bits from various sources, analyzing trends in drill bit sizes used across different industries. This valuable intelligence can inform product development and marketing strategies to meet market demand.