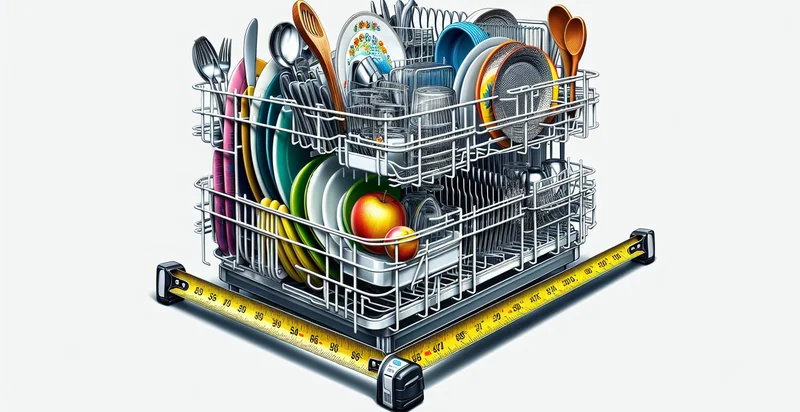

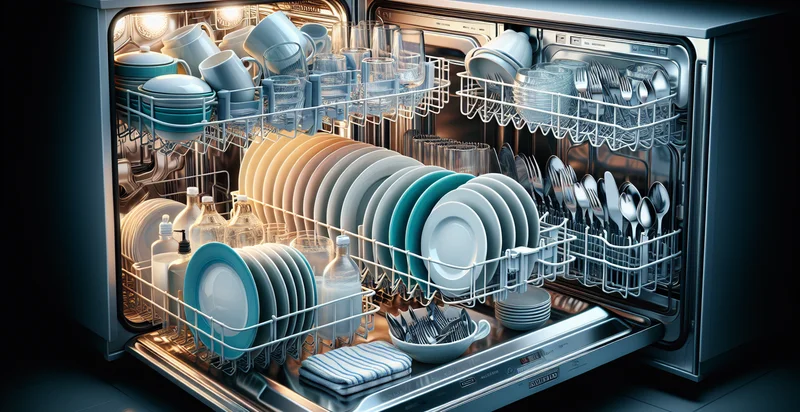

Identify dishwasher conditions

using AI

Below is a free classifier to identify dishwasher conditions. Just upload your image, and our AI will predict the optimal settings for different dishwasher conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("dishwasher-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/dishwasher-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/dishwasher-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal settings for different dishwasher conditions.

This pretrained image model uses a Nyckel-created dataset and has 7 labels, including Average Condition, Excellent Condition, Fair Condition, Good Condition, Like New Condition, Poor Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal settings for different dishwasher conditions).

Whether you're just curious or building dishwasher conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify dishwasher conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Dishwasher Performance Monitoring: This use case involves using the false image classification function to assess the operational conditions of dishwashers in real-time. By analyzing images of the dishwasher interior and its contents, businesses can detect improper loading or blockage issues that may hinder performance and suggest corrective actions.

- Quality Control in Manufacturing: Manufacturers can implement this classification function during the production phase to ensure that dishwashers meet quality standards. Any discrepancies in the internal components, such as the arrangement of spray arms or filters, can trigger alerts, improving overall product reliability.

- Warranty Claim Assessment: Service centers can utilize the function to evaluate images submitted with warranty claims. By identifying dishwashers that have been misused or not properly maintained, businesses can expedite valid claims and reduce fraudulent ones, protecting their bottom line.

- Consumer Behavior Insights: Retailers can leverage this technology to analyze how customers load their dishwashers by collecting and classifying images of user configurations. Insights gained from this data can guide product enhancements, marketing strategies, and user education initiatives that promote optimal usage.

- Maintenance Scheduling: Image classification can be integrated into proactive maintenance systems where images are captured to identify wear and tear conditions on dishwasher components. By recognizing potential issues early, companies can schedule maintenance before severe problems occur, minimizing service interruptions.

- Research and Development Feedback: R&D teams can use the false image classification function to gather user data by capturing images of dishwasher configurations over long periods. This information can inform the development of new features or improved designs that better meet user needs and preferences.

- Smart Home Integration: Businesses developing smart home technology can integrate this classification function with their dishwasher products. This allows the smart system to identify incorrect loading patterns in real-time, providing immediate feedback to users via mobile apps for better appliance use, enhancing customer satisfaction and energy efficiency.