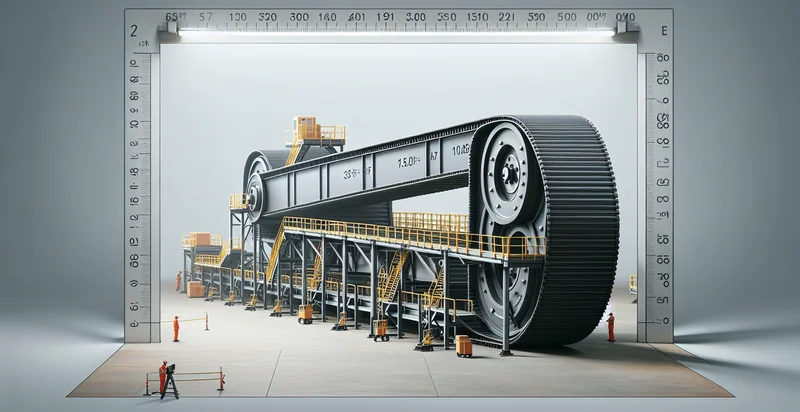

Identify conveyor belt conditions

using AI

Below is a free classifier to identify conveyor belt conditions. Just upload your image, and our AI will predict the condition of items on the conveyor belt - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("conveyor-belt-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/conveyor-belt-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/conveyor-belt-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of items on the conveyor belt.

This pretrained image model uses a Nyckel-created dataset and has 6 labels, including Excellent Condition, Fair Condition, Good Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of items on the conveyor belt).

Whether you're just curious or building conveyor belt conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify conveyor belt conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

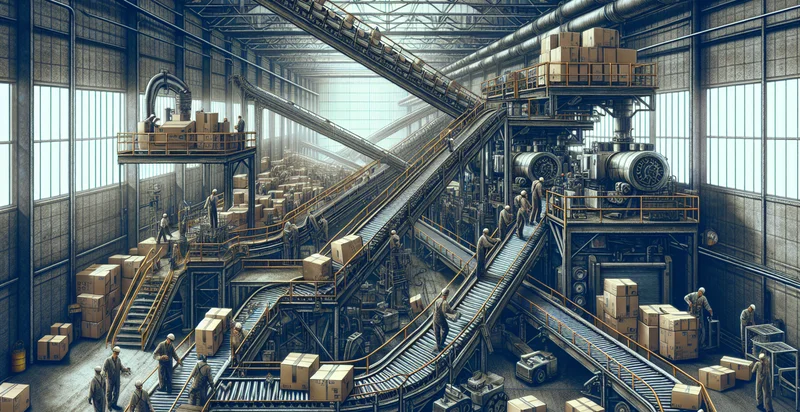

- Quality Control Monitoring: Implement the false image classification function to assess the condition of products on a conveyor belt in real-time. By identifying discrepancies in appearance, manufacturers can quickly remove defective items before they reach packaging.

- Preventive Maintenance Alerts: Utilize the function to monitor conveyor belt conditions for signs of wear or mechanical failure. By analyzing images for deterioration, maintenance teams can receive proactive alerts to address issues before they disrupt operations.

- Inventory Management Optimization: Use the classifier to detect anomalies in the products moving along the conveyor belt. This data can help better manage inventory levels by accurately tracking the flow of goods and reducing bottlenecks in the supply chain.

- Production Line Efficiency Assessment: Apply the classification function to evaluate the effectiveness of the conveyor belt system in real-time. Insights gained can lead to process improvements and adjustments to optimize productivity.

- Safety Compliance Enforcement: Employ the image classification system to ensure safety protocols are being followed along the conveyor belt. By identifying unsafe conditions or operator behavior, businesses can implement corrective measures to enhance workplace safety.

- Automated Sorting Systems: Integrate the classification function into automated sorting machines that direct products to their respective destinations. This reduces manual errors and speeds up the sorting process based on the detected product conditions.

- Training and Simulation Tools: Use the false image classification function as a training aid for staff operating conveyor systems. By simulating various conveyor belt conditions and outcomes, employees can learn to recognize potential issues and improve response strategies.