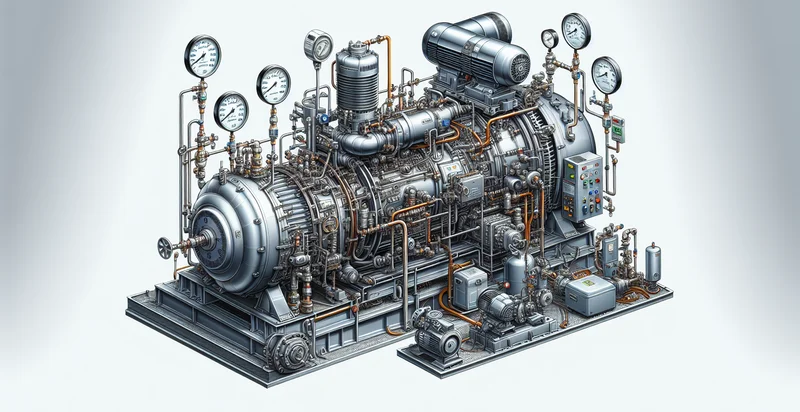

Identify compressor make

using AI

Below is a free classifier to identify compressor make. Just upload your image, and our AI will predict what type of compressor it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("compressor-make", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/compressor-make/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/compressor-make/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what type of compressor it is.

This pretrained image model uses a Nyckel-created dataset and has 19 labels, including Airman, Atlas Copco, Boge, Compair, Dalgakiran, Elgi, Gardner Denver, Goldberg, Haskel and Hitachi.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what type of compressor it is).

Whether you're just curious or building compressor make detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify compressor make at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: The compressor make identifier can be integrated into manufacturing lines to ensure that the correct compressor models are being used in production. It enhances quality control by verifying that parts match specifications, reducing the risk of faulty products reaching the market.

- Inventory Management: Businesses can utilize the compressor make identifier to streamline inventory processes by categorizing compressors according to their manufacturer. This allows for better tracking of parts, management of stock levels, and identification of slow-moving items.

- Preventive Maintenance Scheduling: Service teams can leverage the compressor make identifier to schedule preventive maintenance tailored to specific compressor models. This ensures that maintenance practices are appropriate for the manufacturer's recommendations, which helps in prolonging equipment life and optimizing performance.

- Customer Support Improvement: By identifying the compressor make, support teams can provide more accurate technical assistance to customers. This speeds up response times and enhances customer satisfaction, as technicians can access model-specific documentation and troubleshoot issues effectively.

- Market Research and Business Intelligence: Companies can analyze trends in compressor makes across different industries to drive marketing strategies and product development. This data can help identify which manufacturers are gaining traction, allowing businesses to adapt their offerings accordingly.

- Sales Optimization: Sales teams can rely on the compressor make identifier to tailor their pitches and offerings to clients based on the compressors they already own. Understanding a client’s existing equipment can lead to better cross-selling opportunities and personalized service.

- Compliance and Safety Audits: Organizations can use the compressor make identifier to ensure compliance with industry regulations and safety standards specific to certain manufacturers. This aids in audits and helps maintain adherence to legal requirements, minimizing risks associated with non-compliance.