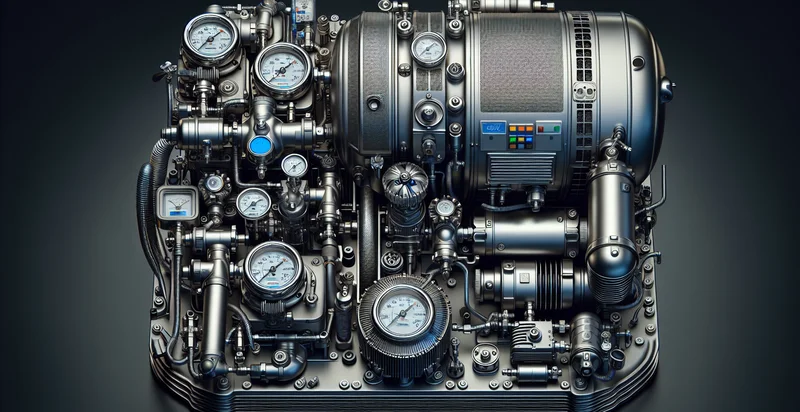

Identify compressor conditions

using AI

Below is a free classifier to identify compressor conditions. Just upload your image, and our AI will predict the operational state of the compressor under various conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("compressor-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/compressor-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/compressor-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational state of the compressor under various conditions.

This pretrained image model uses a Nyckel-created dataset and has 20 labels, including Clean Condition, Corroded, Damaged, Dirty Condition, Excellent Condition, Fair Condition, Fully Operational, Good Condition, High Efficiency and Leaking.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational state of the compressor under various conditions).

Whether you're just curious or building compressor conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify compressor conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The false image classification function can identify discrepancies in compressor conditions based on historical data analysis. This proactive approach allows maintenance teams to replace or repair faulty compressors before a complete failure occurs, minimizing operational downtime and maintenance costs.

- Quality Control in Manufacturing: In manufacturing environments, this function can be implemented to distinguish between acceptable and unacceptable compressor images. By automating the quality control process, businesses can ensure that only compliant compressors are used in production, thus maintaining high-quality standards.

- Energy Efficiency Optimization: The function can be utilized to analyze compressor conditions and identify any inefficiencies. By recognizing false classifications that indicate suboptimal performance, businesses can adjust operational parameters to enhance energy efficiency and reduce operational costs.

- Remote Monitoring Systems: This technology can be integrated into remote monitoring systems for compressors, allowing for real-time image classification. By utilizing the false image classification function, the system can promptly alert operators to potential issues that require attention without physical checks.

- Supplier Quality Assessment: Organizations can use the function to evaluate images of compressors supplied by vendors. This capability ensures that suppliers meet the organization’s quality criteria before accepting products, enhancing supply chain integrity and reducing the risk of receiving defective items.

- Training and Simulation: The false image classification function can serve as a tool for training technicians and engineers. By providing diverse, misclassified compressor images, users can develop a deeper understanding of potential faults and learn to identify symptoms in real-world scenarios effectively.

- Enhanced Safety Protocols: By identifying false classifications related to compressor conditions, companies can strengthen their safety protocols. This function can help ensure that only properly functioning compressors are in operation, reducing the risk of accidents due to equipment failure and promoting a safer work environment.