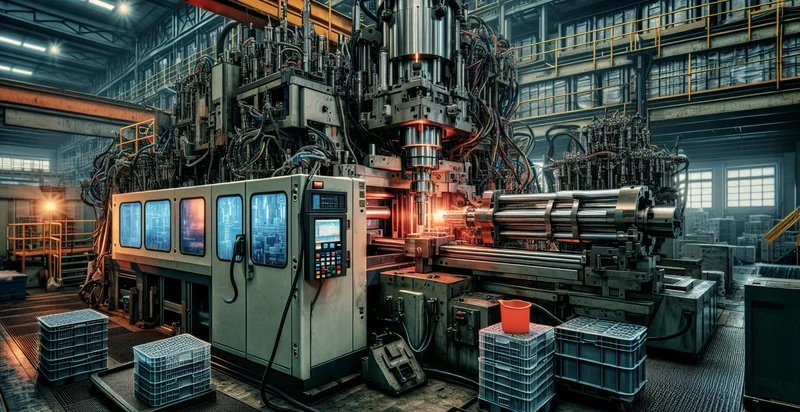

Identify cnc machine conditions

using AI

Below is a free classifier to identify cnc machine conditions. Just upload your image, and our AI will predict the condition of the CNC machine. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("cnc-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/cnc-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/cnc-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the CNC machine..

This pretrained image model uses a Nyckel-created dataset and has 35 labels, including Awaiting Maintenance, Broken Parts, Calibrated, Clean, Cooling Effective, Damaged, Dirty, Excellent Condition, Factory Reset and Fair Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the CNC machine.).

Whether you're just curious or building cnc machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify cnc machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: This use case involves utilizing the false image classification function to identify abnormal conditions in CNC machines. By detecting discrepancies in the expected performance or output quality, manufacturers can schedule maintenance proactively, reducing downtime and increasing operational efficiency.

- Quality Control Assurance: The function can be employed in the quality control process to verify that the finished components meet the required specifications. By classifying images of produced parts, the system can flag any items that do not conform, enabling quick rectification measures to prevent defects from reaching customers.

- Operator Training: This use case focuses on using the identification function as a training tool for CNC machine operators. By simulating various machine conditions and their visual representations, new operators can learn to recognize potential issues and improve their troubleshooting skills.

- Production Optimization: Manufacturers can leverage the classification function to analyze images of operational conditions over time. Insights gained can lead to fine-tuning machine settings and processes, ultimately improving production rates and reducing material waste.

- Remote Monitoring: The false image classification function can be integrated into remote monitoring systems for CNC machines. This setup allows for real-time image analysis, enabling operators and engineers to manage machine health from afar and respond rapidly to emerging issues.

- Performance Benchmarking: Companies can utilize the classification function to gather data on various machine conditions and performance outcomes. This data can help establish benchmarks for optimal operation, guiding improvements in subsequent production runs and leading to overall efficiency.

- Compliance and Safety Audits: The classification function can assist in ensuring that CNC machines are operating under safe and compliant conditions. Regular analysis of image output can help identify safety hazards, thereby maintaining a safe working environment for operators and monitoring adherence to industry regulations.