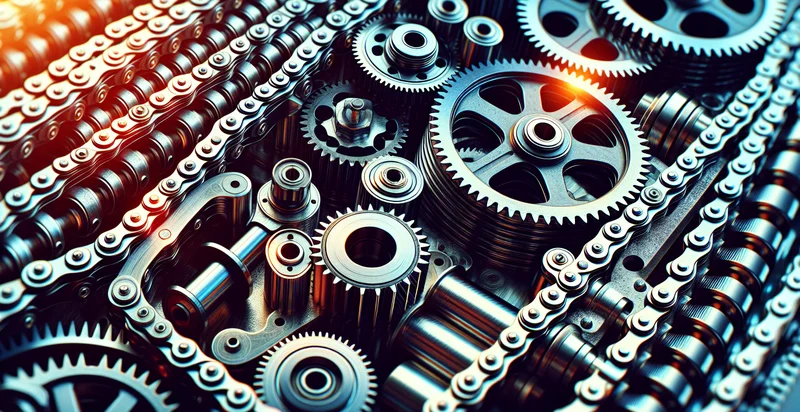

Identify chain drive conditions

using AI

Below is a free classifier to identify chain drive conditions. Just upload your image, and our AI will predict the optimal performance condition for chain drives - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("chain-drive-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/chain-drive-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/chain-drive-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal performance condition for chain drives.

This pretrained image model uses a Nyckel-created dataset and has 6 labels, including Excellent Condition, Fair Condition, Good Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal performance condition for chain drives).

Whether you're just curious or building chain drive conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify chain drive conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Preventive Maintenance Scheduler: This use case involves integrating the false image classification function into a maintenance management system to help predict when chain drive components may require service. By analyzing real-time images of chain drives, the system can identify fraudulent or misleading representations of wear, allowing for timely maintenance and reducing unexpected downtimes.

- Quality Control in Manufacturing: In this scenario, manufacturers can utilize the image classification function in their quality assurance processes. The system will evaluate images of chain drives to detect falsely represented defects, ensuring only products that meet quality standards reach the market.

- Regulatory Compliance Monitoring: Companies in regulated industries can deploy the classification function to ensure compliance with safety and operational guidelines for chain drives. By detecting and flagging fraudulent images that misrepresent compliance, organizations can maintain adequate records and avoid legal penalties.

- Training Simulator for Technicians: This use case involves using the image classification function in training programs for technicians. Unrealistic or fraudulent images of chain drives can be filtered out in training materials, allowing new technicians to focus on genuine scenarios and improve their diagnostic skills.

- Supplier Verification Process: Businesses can implement the false image classification function to verify the authenticity of chain drives supplied by manufacturers. By screening images provided by suppliers for inaccuracies, companies can ensure they are sourcing reliable and genuine products, thereby reducing the risk of counterfeit components.

- Enhanced Customer Support Solutions: Integrating the classification function into customer support could aid in resolving client issues with chain drive systems. By automatically analyzing images submitted by customers, the system can determine if deceptive representations exist, leading to more accurate problem assessment and resolution.

- Smart Inventory Management Systems: In logistics and supply chain operations, this use case involves leveraging the classification function to assess the quality of chain drives in inventory. By filtering out misleading images of products, businesses can better manage stock levels, ensuring that only valid and high-quality items are available for sale or use.