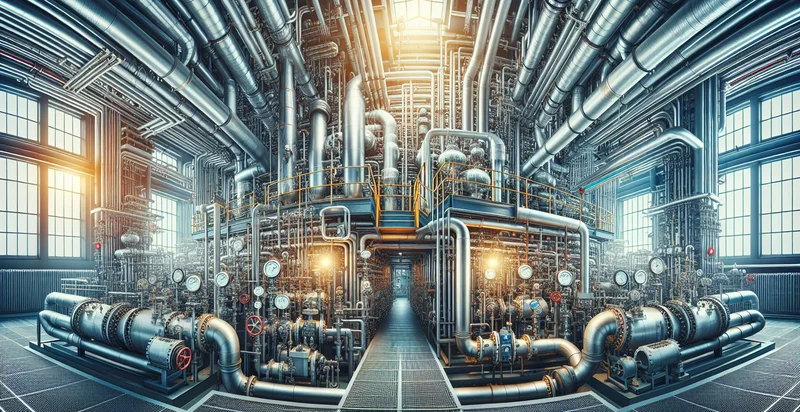

Identify boiler conditions

using AI

Below is a free classifier to identify boiler conditions. Just upload your image, and our AI will predict the condition of the boiler. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("boiler-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/boiler-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/boiler-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the boiler..

This pretrained image model uses a Nyckel-created dataset and has 16 labels, including Excellent Condition, Fair Condition, Functioning Well, Good Condition, Inoperable, Leaky, Needs Maintenance, New Installation, Operational and Out Of Service.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the boiler.).

Whether you're just curious or building boiler conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify boiler conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: This function can be used to analyze boiler conditions in real-time, identifying abnormal patterns that indicate potential failures. By flagging these discrepancies early, companies can schedule preventive maintenance, reducing downtime and repair costs.

- Quality Control in Manufacturing: In manufacturing industries that rely on steam boilers, the classification function can ensure that boilers are operating within optimal conditions. This enhances product quality by preventing defects caused by inconsistent steam pressure or temperature.

- Safety Compliance Monitoring: The boiler conditions identifier can monitor operational parameters to ensure compliance with safety regulations. By continuously assessing these parameters, businesses can proactively address safety violations that could result in penalties or hazardous incidents.

- Energy Efficiency Optimization: By classifying boiler conditions, companies can identify inefficiencies in operations. This information can lead to adjustments in fuel consumption and other parameters, ultimately promoting energy savings and environmental sustainability.

- Asset Management: The function can be integrated into an asset management system to provide insights on the health of boiler equipment. This helps managers make informed decisions about asset lifecycle, replacement, or upgrades based on performance data.

- Remote Monitoring Solutions: The boiler conditions identifier can be deployed in IoT systems for remote monitoring of boiler conditions. This allows operators to maintain oversight and react promptly to any identified issues without needing to be physically present on-site.

- Training and Simulation: This classification function can serve as an educational tool for training technicians on boiler operation and maintenance. By simulating various boiler conditions, trainees can learn to recognize and correct issues before they lead to system failures in real-world scenarios.