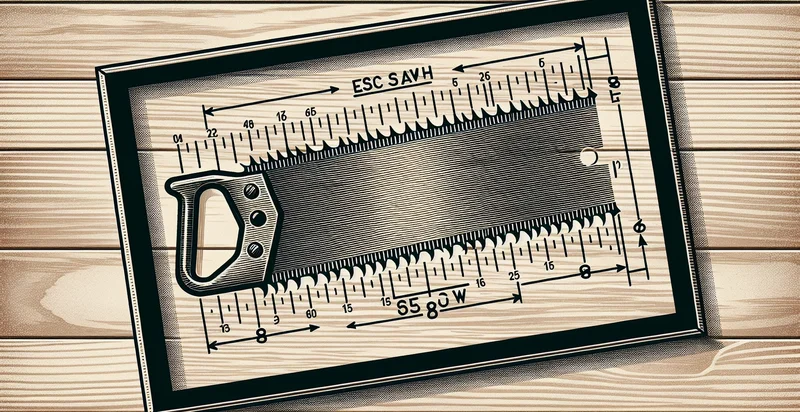

Identify blade sharpness

using AI

Below is a free classifier to identify blade sharpness. Just upload your image, and our AI will predict if the blade is sharp - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("blade-sharpness", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/blade-sharpness/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/blade-sharpness/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the blade is sharp.

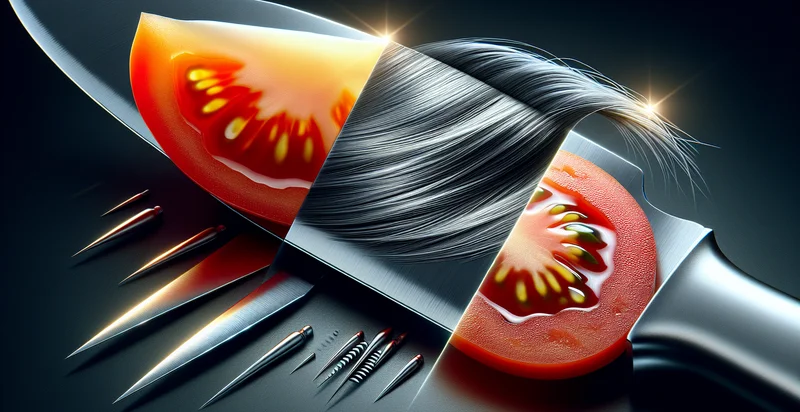

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Dull and Sharp.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the blade is sharp).

Whether you're just curious or building blade sharpness detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify blade sharpness at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Manufacturing Quality Control: The blade sharpness identifier can be integrated into manufacturing lines to automatically assess the sharpness of blades used in production. This allows for real-time quality control, reducing the likelihood of product defects and ensuring that only sharp, high-quality blades are used in the process.

- Metal Fabrication Industry: In metal fabrication, sharp blades are crucial for precision cutting. The sharpness identifier can help operators monitor tool conditions, leading to proactive maintenance scheduling and minimizing downtime due to dull blades.

- Culinary Equipment Maintenance: Restaurants and culinary institutions can utilize this technology to regularly check the sharpness of their kitchen knives and tools. By ensuring that blades are kept sharp, chefs can improve efficiency and safety in food preparation.

- Agricultural Equipment Monitoring: Farmers can employ the identifier to monitor the sharpness of blades on devices like plows and harvesters. This ensures optimal performance during critical farming tasks, leading to better yields and reduced wear on equipment.

- Forestry and Logging Operations: In forestry, maintaining sharp cutting tools is essential for efficient tree felling and processing. The identification function can be used to quickly assess and optimize blade conditions in the field, improving productivity and reducing fatigue for operators.

- Tool Rental Services: Businesses that rent out cutting equipment can implement this function to assess and ensure the sharpness of tools before they are rented out. This enhances customer satisfaction by guaranteeing that rental blades are in optimal condition upon delivery.

- Product Research and Development: Companies involved in developing new cutting tools can use the sharpness identifier in their research processes. By analyzing how blade sharpness affects performance and material quality, R&D teams can design better, more efficient cutting tools.