Identify belt drive conditions

using AI

Below is a free classifier to identify belt drive conditions. Just upload your image, and our AI will predict the condition of the belt drive system - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("belt-drive-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/belt-drive-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/belt-drive-conditions/invoke

How this classifier works

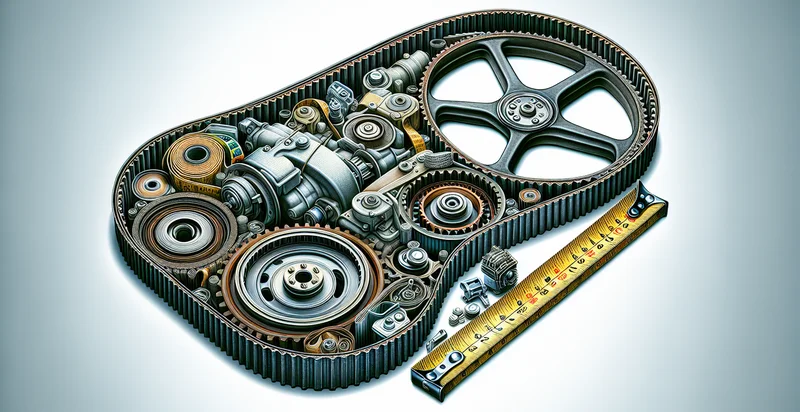

To start, upload your image. Our AI tool will then predict the condition of the belt drive system.

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Damaged Condition, Excellent Condition, Fair Condition, Good Condition, Like New Condition, Poor Condition, Repaired Condition, Very Good Condition, Very Poor Condition and Worn Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the belt drive system).

Whether you're just curious or building belt drive conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify belt drive conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The false image classification function helps identify and assess belt drive conditions in machinery. By accurately determining potential failures, organizations can schedule proactive maintenance, reducing downtime and maintenance costs.

- Quality Control in Manufacturing: This function can be integrated into manufacturing quality control systems to ensure that only correctly classified belt drives are used in production. By eliminating false positives, manufacturers can improve reliability and reduce defects in end products.

- Safety Monitoring: In industrial environments, the identification of belt drive conditions is critical for safety. This function can help detect potentially hazardous belt failures, enabling immediate interventions to prevent accidents and enhance workplace safety.

- Performance Optimization: By analyzing classified belt drive conditions, businesses can optimize their operations for better efficiency. The data can guide adjustments in usage patterns and load management, leading to improved performance and energy savings.

- Inventory Management: The classification function can assist in maintaining appropriate inventory levels of spare parts for belt drives. By predicting when failures are likely to occur, businesses can better plan their inventory, reducing overstock and stockouts.

- Customer Service Enhancement: Companies can use the function to enhance customer service by providing real-time updates on the condition of belt drive systems. Clients can receive alerts about potential issues before they escalate, leading to improved satisfaction and loyalty.

- Research and Development: The insights gained from the false image classification function can drive R&D efforts in developing better belt drive designs. By understanding failure modes and conditions, engineers can innovate new solutions that improve durability and extend the lifespan of belt systems.