Identify belt conditions

using AI

Below is a free classifier to identify belt conditions. Just upload your image, and our AI will predict the condition of the belt. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("belt-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/belt-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/belt-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the belt..

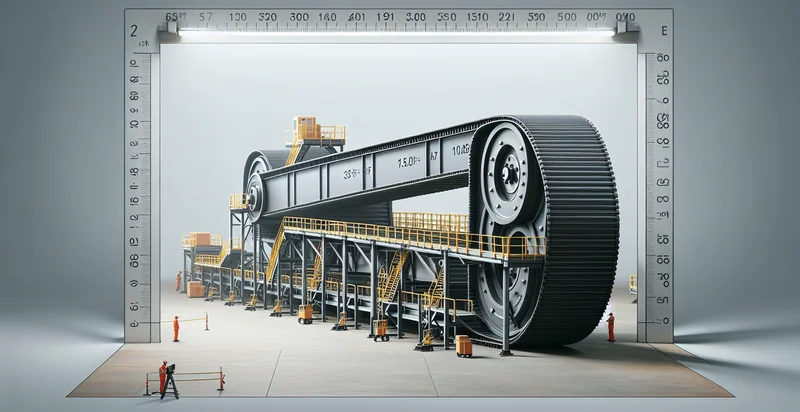

This pretrained image model uses a Nyckel-created dataset and has 15 labels, including Brittle, Broken, Cracked, Dented, Discolored, Faded, Frayed, Intact, Loose and Missing Buckle.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the belt.).

Whether you're just curious or building belt conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify belt conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

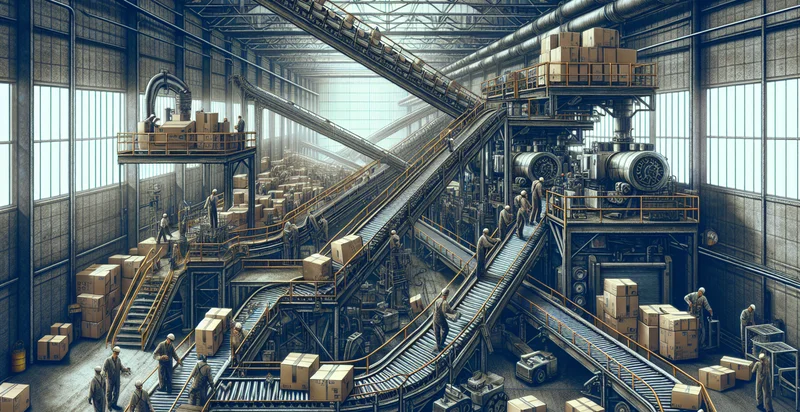

- Quality Control in Manufacturing: This function can be integrated into the production line to automatically identify faulty or substandard belts before they reach the packaging stage. By ensuring only high-quality items pass through, manufacturers can reduce returns and improve customer satisfaction.

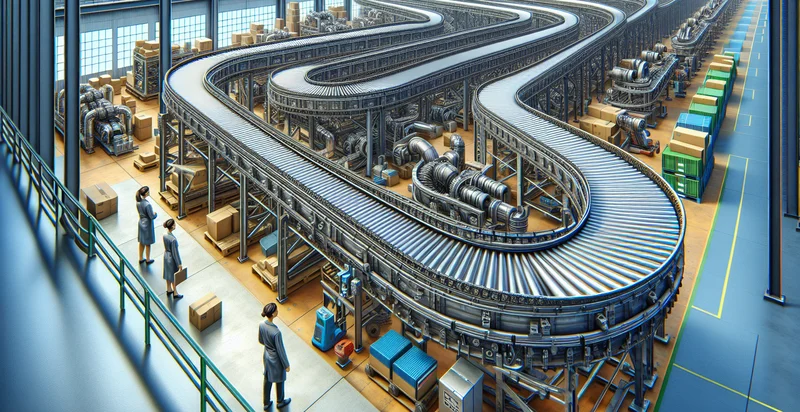

- Predictive Maintenance in Equipment: By monitoring the condition of conveyor belts and other critical machinery components, this function can predict when a belt is nearing the end of its lifespan. This allows companies to perform maintenance proactively, minimizing downtime and repair costs.

- Safety Compliance in Warehousing: Warehouses need to maintain stringent safety standards; this function can help identify worn or damaged belts that could pose a risk to workers. By ensuring only safe equipment is in operation, companies can reduce workplace accidents and liability.

- Inventory Management for Retail: Retailers can use this function to check the conditions of belts used in display setups or conveyor systems. By assessing the quality of these items, businesses can effectively manage inventory, replacing only those that are genuinely worn or damaged.

- Sustainable Manufacturing Practices: This classification function can help in identifying belts that can be recycled or repurposed effectively. By minimizing waste and promoting sustainability, manufacturers can enhance their corporate responsibility profiles and reduce environmental impact.

- Customer Service Enhancement: Businesses that provide belts as part of their product lines can use this function to identify any quality issues before shipping. This leads to improved customer satisfaction and decreased likelihood of returns, as customers receive products in optimal condition.

- Research and Development: Companies developing new materials for belts can utilize this function to analyze the performance of various prototypes. By classifying and assessing conditions, R&D teams can make informed decisions on material improvements and innovations based on empirical data.