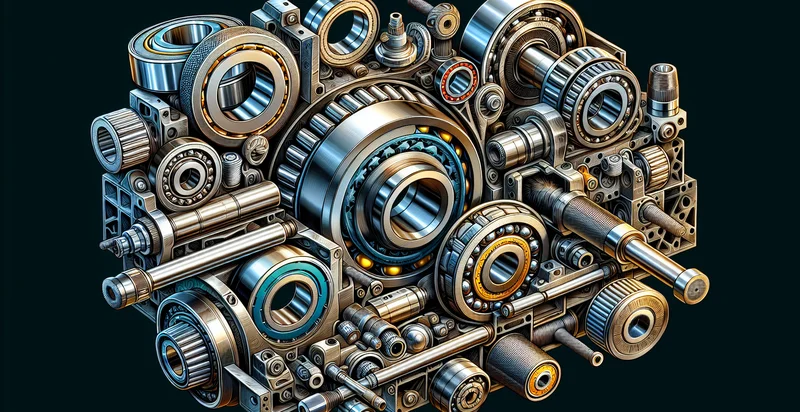

Identify bearing wear

using AI

Below is a free classifier to identify bearing wear. Just upload your image, and our AI will predict the level of wear in different types of bearings. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("bearing-wear", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/bearing-wear/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/bearing-wear/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the level of wear in different types of bearings..

This pretrained image model uses a Nyckel-created dataset and has 7 labels, including Critical, Excessive, Minimal, Moderate, None, Severe and Significant.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the level of wear in different types of bearings.).

Whether you're just curious or building bearing wear detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify bearing wear at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The bearing wear identifier can be integrated into predictive maintenance programs for industrial machinery. By identifying wear patterns early, organizations can schedule maintenance before catastrophic failures occur, reducing downtime and repair costs.

- Quality Control: Manufacturers can utilize the bearing wear identifier as part of their quality control processes. This function can help ensure that only components meeting wear standards are used in final products, thereby improving overall product reliability.

- Fleet Management: Fleet operators can leverage the bearing wear identifier to monitor the condition of bearings in vehicles or machinery on-the-road. This proactive monitoring can extend asset life, improve safety, and reduce operational costs by preventing unexpected breakdowns.

- Warranty Analysis: Bearing manufacturers can employ the wear identifier to analyze warranty claims related to bearing failures. By understanding the wear patterns associated with different conditions, they can improve design, increase customer satisfaction, and adjust warranty terms accordingly.

- Remote Monitoring: The bearing wear identifier can be part of IoT solutions for remote monitoring of equipment. By continuously assessing the wear state of bearings, companies can gain real-time insights, allowing them to respond quickly to emerging issues.

- Research and Development: R&D teams can use the bearing wear identifier in developing new bearing technologies or materials. By analyzing wear under different conditions, teams can innovate and create more durable products, enhancing competitive advantage.

- Training and Simulation: The identifier can be utilized in training programs for technicians and engineers. By simulating various wear conditions and outcomes, trainees can gain hands-on experience in diagnosing and addressing bearing wear issues, enhancing their skills and knowledge.