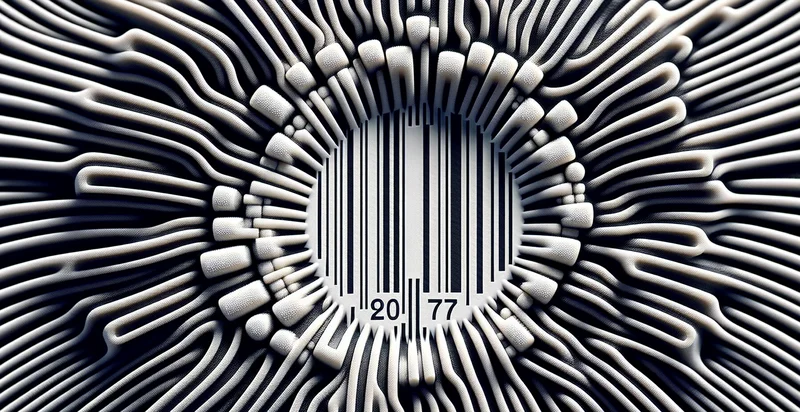

Identify barcode scanner conditions

using AI

Below is a free classifier to identify barcode scanner conditions. Just upload your image, and our AI will predict what type of barcode it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("barcode-scanner-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/barcode-scanner-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/barcode-scanner-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what type of barcode it is.

This pretrained image model uses a Nyckel-created dataset and has 5 labels, including Excellent Condition, Fair Condition, Good Condition, Poor Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what type of barcode it is).

Whether you're just curious or building barcode scanner conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify barcode scanner conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Inventory Management: This function can automatically assess the conditions of barcodes scanned during inventory checks. By identifying false image classifications, businesses can ensure accuracy in their stock levels and prevent discrepancies caused by damaged or unreadable barcodes.

- Quality Control in Manufacturing: In a production line where barcodes are used to track products, this function can monitor the condition of barcode images. By flagging falsified or poor-quality barcode images, it helps maintain quality standards and reduces the number of defective products shipped.

- Retail Checkout Optimization: Retailers can employ this function at checkout points to verify the condition of barcodes on products. By identifying any incorrect scans immediately, it speeds up the checkout process and enhances customer satisfaction by reducing wait times.

- Logistics and Shipping Verification: In logistics, accurate scanning of barcodes is essential for tracking shipments. This function can be deployed to detect and report false image classifications, helping companies ensure that packages are correctly logged and routed, minimizing loss and misdelivery.

- Compliance and Regulatory Auditing: Companies can use this function during compliance checks to verify that barcodes meet required standards. By identifying problematic barcode conditions, organizations can address compliance issues proactively, avoiding potential penalties.

- Returns Processing Automation: In retail, return processes often involve checking barcodes on returned items. This function can help automate the verification process by identifying misclassified barcodes, streamlining the returns handling and improving efficiency in managing returns.

- User Training and Support: The function can also serve as a training tool within organizations to educate employees about proper barcode scanning techniques. By demonstrating how false image classifications can occur, it fosters a better understanding of barcode usage and minimizes future errors in operations.