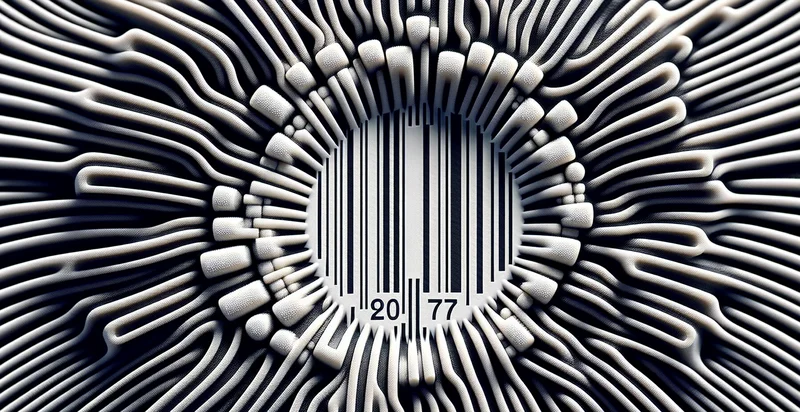

Identify barcode quality

using AI

Below is a free classifier to identify barcode quality. Just upload your image, and our AI will predict the quality of the barcode. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("barcode-quality", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/barcode-quality/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/barcode-quality/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the quality of the barcode..

This pretrained image model uses a Nyckel-created dataset and has 16 labels, including Blurred, Clean, Clear, Complete, Damaged, Dirty, Distorted, Faded, Incomplete and Legible.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the quality of the barcode.).

Whether you're just curious or building barcode quality detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify barcode quality at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This use case involves integrating the barcode quality identifier into the manufacturing process to automatically assess the quality of barcodes printed on products. By quickly identifying defective barcodes, manufacturers can reduce wastage and ensure that all products are properly scannable, leading to smoother inventory management.

- Warehouse Management Optimization: In warehouse settings, the barcode quality identifier can be employed to verify the quality of barcodes on incoming and outgoing shipments. This helps optimize logistics operations by ensuring that all scanned items are accurately tracked, reducing delays caused by unreadable barcodes.

- Retail Inventory Auditing: Retailers can leverage the barcode quality identifier during inventory audits to promptly assess the condition of barcodes on products. By identifying which items have damaged or poorly printed barcodes, retailers can take corrective actions to maintain accurate stock levels and improve customer experience.

- E-commerce Fulfillment Accuracy: An e-commerce platform can integrate the barcode quality identifier into its fulfillment processes to ensure that all shipped items have high-quality barcodes. This reduces the likelihood of errors during shipping and returns, ultimately enhancing customer satisfaction and operational efficiency.

- Supply Chain Traceability: The barcode quality identifier can enhance supply chain traceability by confirming the quality of barcodes on each product as it moves through the supply chain. By ensuring that only high-quality barcodes are used, companies can maintain accurate tracking of products, which is vital for inventory control and regulatory compliance.

- Automated Retail Checkout Systems: By implementing the barcode quality identifier in self-checkout systems, retailers can improve the accuracy of transactions. The system will flag any poor-quality barcodes, prompting assistance from staff and ensuring that customers can complete their purchases without significant delays.

- Product Recall Management: In the event of a product recall, the barcode quality identifier can aid companies in identifying affected products quickly by verifying the quality of the barcodes on store shelves. This functionality helps streamline the recall process, ensuring that only the products associated with the recall are addressed, minimizing brand risk and protecting consumer safety.