Identify barcode environmental wear

using AI

Below is a free classifier to identify barcode environmental wear. Just upload your image, and our AI will predict the level of environmental wear on different barcode types - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("barcode-environmental-wear", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/barcode-environmental-wear/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/barcode-environmental-wear/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the level of environmental wear on different barcode types.

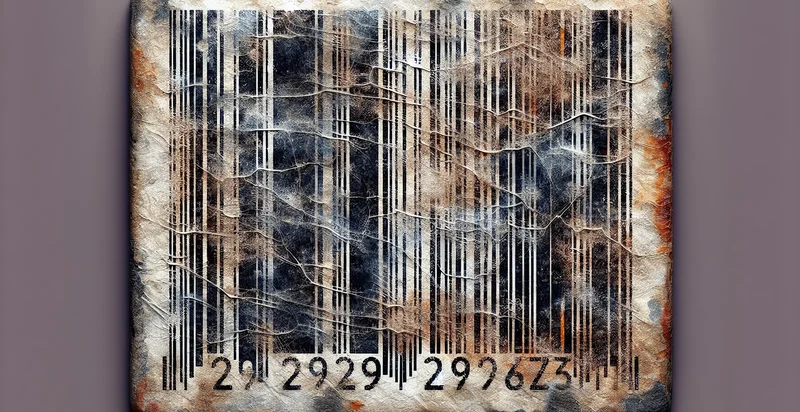

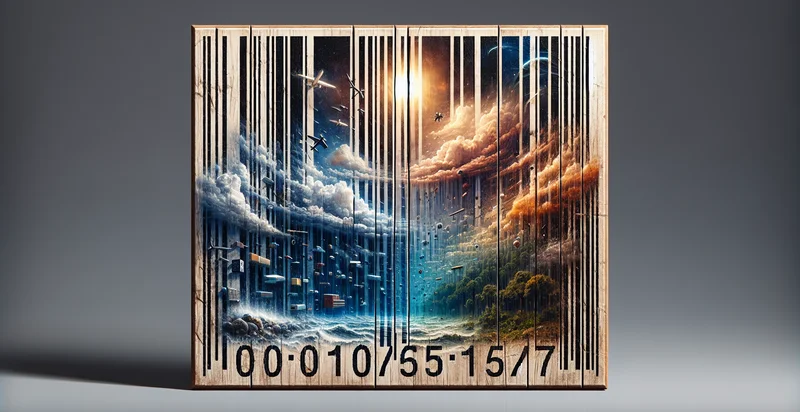

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Contaminated, Damaged, Faded, Light Wear, Missing, Moderate Wear, Protected and Severe Wear.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the level of environmental wear on different barcode types).

Whether you're just curious or building barcode environmental wear detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify barcode environmental wear at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Inventory Management: The barcode environmental wear identifier can be integrated into supply chain management systems to monitor the condition of products stored in varying environmental conditions. By assessing wear and potential degradation, businesses can make informed decisions about inventory turnover and optimize storage practices.

- Quality Control in Manufacturing: Manufacturers can employ the identifier to assess the wear on barcode labels during production processes. This ensures that products shipped to retailers maintain high quality and are easily scannable, reducing the chances of returns and improving overall customer satisfaction.

- Asset Tracking: Companies can utilize the technology to track physical assets that may be exposed to harsh environmental conditions. By identifying wear on barcodes, organizations can schedule maintenance or replacements, thereby ensuring that assets remain in operational condition while managing lifecycle costs effectively.

- Retail Compliance: Retailers can implement the identifier to ensure that products on shelves remain scannable and meet industry standards for barcode quality. This not only helps in compliance with regulations but also enhances the customer checkout experience by minimizing scanning errors.

- E-commerce Returns Management: The environmental wear identifier can play a crucial role in the returns process for e-commerce businesses. By analyzing returned items' barcodes for wear and damage, companies can determine whether the returned products were improperly stored or handled, enabling better return policies and inventory strategies.

- Environmental Impact Assessment: Organizations focused on sustainability can use this identifier to evaluate the wear on barcodes in relation to environmental exposure. This can provide insights into the durability of materials used in packaging and labeling, facilitating more eco-friendly choices in production and sourcing.

- Automated Supply Chain Alerts: By integrating the identifier into inventory management systems, businesses can create automated alerts based on the condition of barcodes. This proactive approach allows companies to intervene before wear leads to operational disruptions, ensuring a smoother supply chain process.