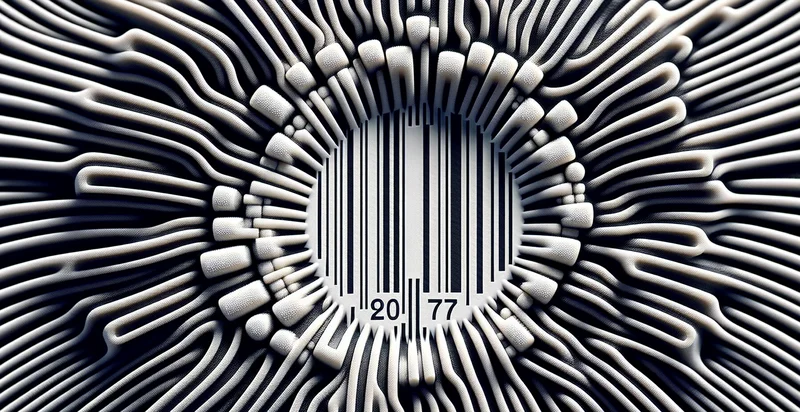

Identify barcode damage level

using AI

Below is a free classifier to identify barcode damage level. Just upload your image, and our AI will predict the level of damage to the barcode - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("barcode-damage-level", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/barcode-damage-level/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/barcode-damage-level/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the level of damage to the barcode.

This pretrained image model uses a Nyckel-created dataset and has 5 labels, including Minor Damage, Moderate Damage, Pristine, Severe Damage and Unreadable.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the level of damage to the barcode).

Whether you're just curious or building barcode damage level detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify barcode damage level at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

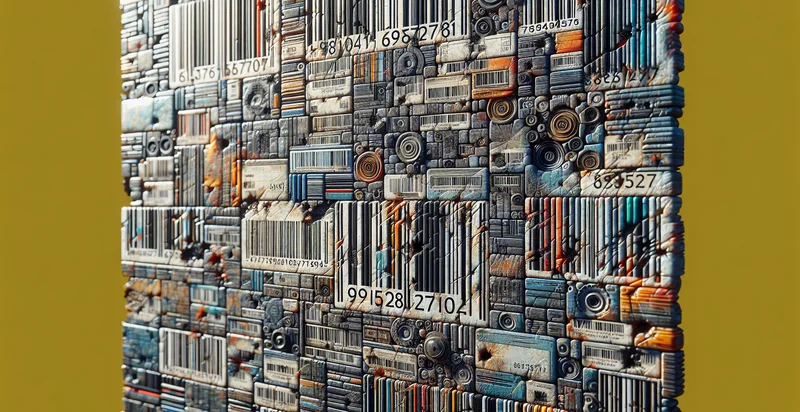

- Quality Control in Manufacturing: The barcode damage level identifier can be integrated into manufacturing lines to assess the integrity of packaging. By evaluating the damage levels of barcodes in real-time, companies can prevent defective products from reaching consumers and optimize their production processes.

- Retail Inventory Management: Retailers can utilize the barcode damage level identifier to ensure that all products are properly scanned and categorized. By detecting damaged barcodes during inventory checks, stores can maintain accurate stock levels and avoid discrepancies that could result in lost sales or excess inventory.

- Logistics and Supply Chain Optimization: In logistics, the barcode damage level identifier can help streamline the receiving and shipping processes. By quickly identifying damaged barcodes on incoming shipments, companies can reduce delays and improve the accuracy of their inventory records, leading to more efficient operations.

- E-commerce Returns Processing: E-commerce businesses can utilize this function to evaluate the condition of returned products more effectively. By classifying the damage level of barcodes, companies can better determine whether to restock items or categorize them for discounting or disposal, reducing losses from unresalable goods.

- Customer Experience Improvement: Retailers can enhance the customer experience by using the barcode damage level identifier in point-of-sale systems. Ensuring accurate scanning of products and minimizing checkout frustrations related to damaged barcodes can lead to quicker transactions and increased customer satisfaction.

- Automated Warehousing Solutions: In automated warehouses, robots equipped with the barcode damage level identifier can identify and reject damaged items with minimal human intervention. This capability enhances per-formance efficiency and helps maintain high standards for item integrity during storage and retrieval operations.

- Compliance and Reporting: Businesses in regulated industries can leverage the barcode damage level identifier to maintain compliance with labeling and packaging regulations. By ensuring that only barcodes in acceptable condition are used on products, companies can prevent penalties and ensure consumer safety while fostering accountability in their operations.