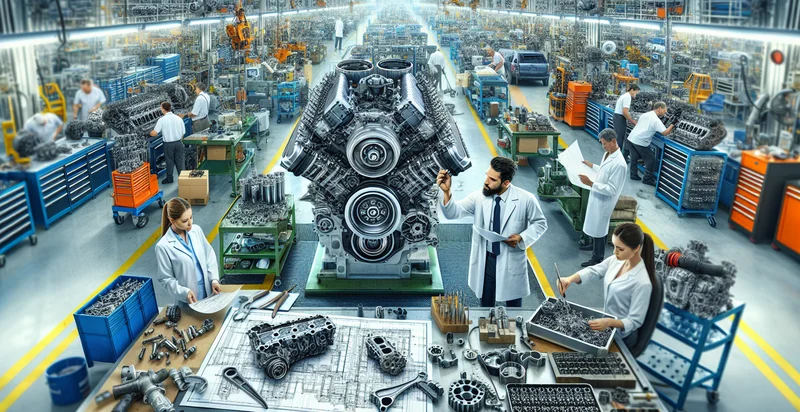

Identify axle manufacturer

using AI

Below is a free classifier to identify axle manufacturer. Just upload your image, and our AI will predict the type of axle being manufactured - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("axle-manufacturer", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/axle-manufacturer/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/axle-manufacturer/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the type of axle being manufactured.

This pretrained image model uses a Nyckel-created dataset and has 25 labels, including Aap, Acdelco, Alcoa, Bca, Continental, Dana, Dormant, Eaton, Exedy and Firestone.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the type of axle being manufactured).

Whether you're just curious or building axle manufacturer detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify axle manufacturer at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

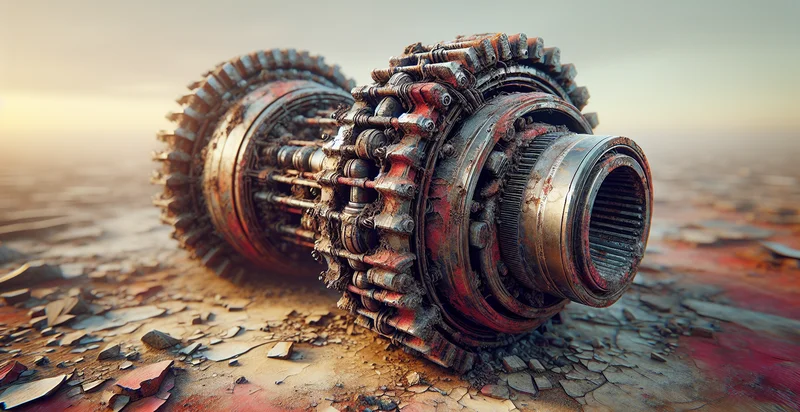

- Quality Control: The axle manufacturer can implement false image classification to automatically detect defective products during the manufacturing process. By analyzing images of axles, the system can identify anomalies or substandard quality, ensuring that only compliant axles reach the distribution stage.

- Inventory Management: The classification function can streamline the inventory process by accurately identifying axles from captured images. This minimizes human error, enables better tracking of stock levels, and enhances the efficiency of warehouse operations.

- Supplier Verification: The axle manufacturer can use false image classification to verify the authenticity of axle parts received from suppliers. By comparing images of incoming parts against established standards, manufacturers can ensure they are receiving quality materials and reduce counterfeit risks.

- Maintenance Predictions: By analyzing images of axles in use, the classification function can help predict maintenance needs. This aids in scheduling services before issues arise, minimizing downtime and enhancing operational efficiency.

- Compliance Monitoring: The axle manufacturer can utilize image classification to ensure that products comply with industry standards and regulations. By automatically assessing images against compliance criteria, the process speeds up audits and quality assurance reviews.

- Market Research: Analyzing images of competitor axles can provide insights into design trends and material use. By classifying these images, the manufacturer can identify competitive advantages and inform product development strategies.

- Customer Feedback Analysis: The axle manufacturer can implement the classification function to analyze customer-submitted images of axle issues. This helps in understanding common problems, leading to better customer service and continuous product improvements based on real-world usage.