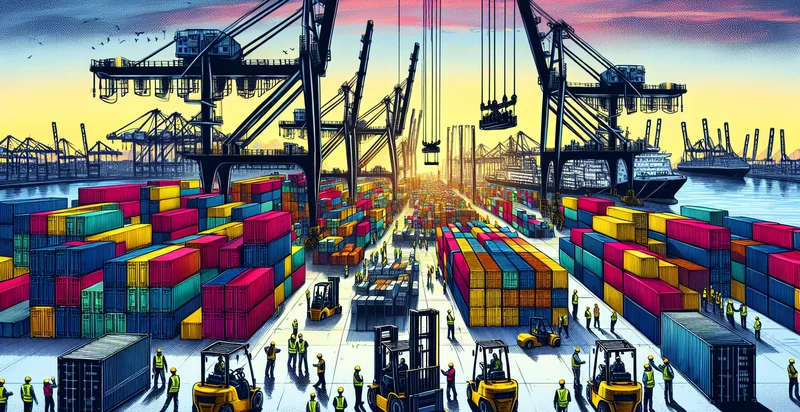

Identify assembly line conditions

using AI

Below is a free classifier to identify assembly line conditions. Just upload your image, and our AI will predict the type of defect present in assembly line conditions. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("assembly-line-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/assembly-line-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/assembly-line-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the type of defect present in assembly line conditions..

This pretrained image model uses a Nyckel-created dataset and has 20 labels, including Adequate Conditions, Clean Conditions, Dirty Conditions, Disorganized Conditions, Excellent Condition, Fair Condition, Good Condition, Modern Equipment, Noisy Conditions and Organized Conditions.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the type of defect present in assembly line conditions.).

Whether you're just curious or building assembly line conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify assembly line conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

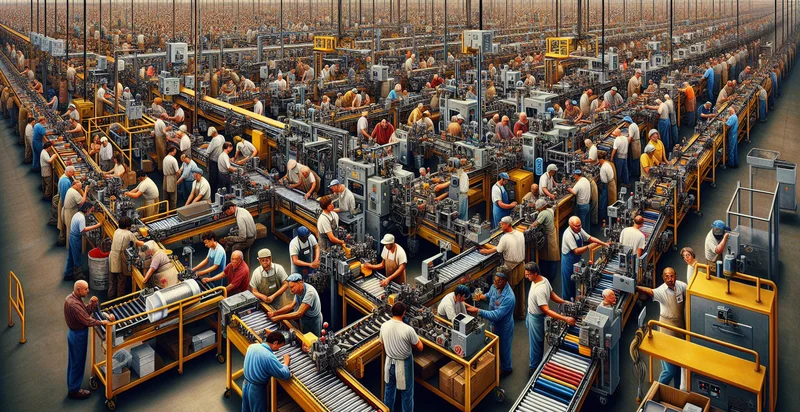

- Quality Control Automation: This function can be employed on assembly lines to automatically assess images of products against quality standards. By quickly identifying false images or defects, manufacturers can prevent substandard products from progressing further down the production line, thereby reducing waste and improving overall quality.

- Safety Monitoring: The image classification function can be utilized to ensure compliance with safety conditions on assembly lines. By monitoring images of working conditions, it can identify unsafe practices or irregularities, enabling prompt interventions to protect worker safety.

- Equipment Maintenance Prediction: By classifying images of machinery and equipment under assembly line conditions, this function can identify wear and tear. Analysis of false images might indicate maintenance needs or the potential for equipment failure, thereby enhancing preventative maintenance schedules.

- Inventory Management: The function can analyze images of inventory on assembly lines to ensure that components are correctly identified and available. Detecting false images can help streamline inventory tracking and reduce bottlenecks caused by misplaced or incorrect items.

- Process Optimization: Utilizing this image classification function can aid in monitoring assembly line efficiency. By identifying false images that reveal inefficiencies or process errors, management can make data-driven adjustments to enhance productivity and reduce downtimes.

- Compliance Auditing: This function can support compliance auditing processes by verifying that assembly line operations adhere to industry standards. It can analyze images to identify discrepancies that may lead to non-compliance, enabling proactive measures before formal audits.

- Training and Simulation: The image classification function can be used in training environments to create realistic scenarios for workers on assembly lines. By utilizing false images in simulations, trainees can learn to identify potential issues before encountering them in real-world conditions, improving their readiness for actual production tasks.