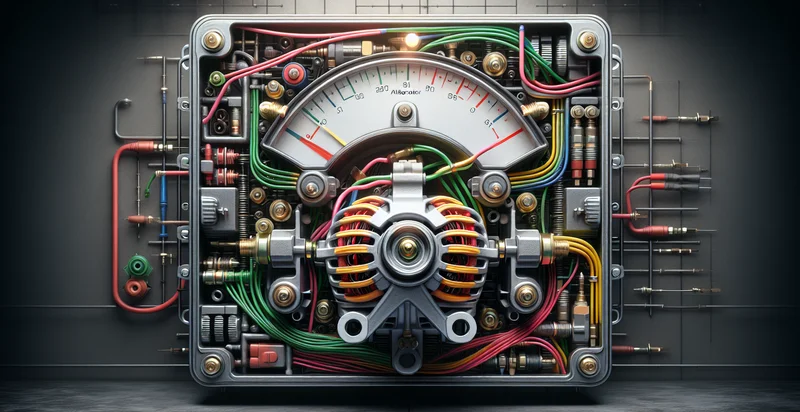

Identify alternator manufacturer

using AI

Below is a free classifier to identify alternator manufacturer. Just upload your image, and our AI will predict what type of alternator it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("alternator-manufacturer", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/alternator-manufacturer/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/alternator-manufacturer/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what type of alternator it is.

This pretrained image model uses a Nyckel-created dataset and has 44 labels, including Ac Delco, Bba Reman, Bosch, Carquest, Cummins, Delco Remy, Delphi, Denso, Federal Mogul and Ford.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what type of alternator it is).

Whether you're just curious or building alternator manufacturer detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify alternator manufacturer at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control: This function can be utilized in the quality assurance process to identify false images of alternators during inspection. By automating the classification of images captured on the manufacturing line, it helps ensure only compliant products proceed to packaging.

- Supplier Quality Assessment: Alternator manufacturers can implement this function to evaluate images of parts received from suppliers. By identifying incorrect or faulty components early in the process, manufacturers can avoid costly assembly errors and maintain production schedules.

- Marketing Material Verification: The function can be deployed to verify that marketing material, such as product images used in advertisements, accurately represents the alternators produced. This helps maintain brand integrity and customer trust by ensuring that consumers see accurate depictions of products.

- Warranty Validation: Manufacturers can use this image classification function to assess images submitted by customers claiming warranty services. By confirming whether the alternators in question match the ones sold, the company can streamline the warranty process and reduce fraud.

- Image Archive Management: This function can aid in organizing and managing image databases of alternators by classifying images correctly and flagging false ones. This maintains a clean and usable archive, which is essential for future references or audits.

- Research and Development: During the R&D phase for new alternator designs, this classification function can be used to assess design prototypes through image analysis. It can help identify design flaws or inconsistencies that may not be evident during physical inspections.

- Compliance and Standards Reporting: This function can assist manufacturers in ensuring that images of their alternators meet industry compliance standards. By classifying and validating images against regulatory requirements, manufacturers can prepare accurate documentation for audits and compliance checks.