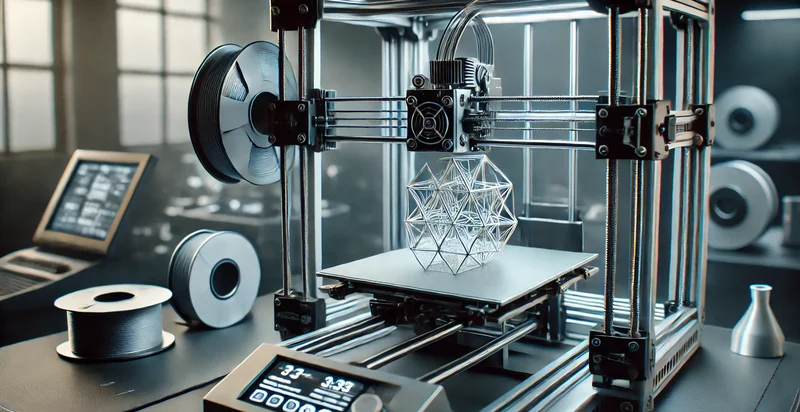

Identify 3d printer conditions

using AI

Below is a free classifier to identify 3d printer conditions. Just upload your image, and our AI will predict the optimal conditions for 3D printing materials - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("3d-printer-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/3d-printer-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/3d-printer-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal conditions for 3D printing materials.

This pretrained image model uses a Nyckel-created dataset and has 12 labels, including Excellent Condition, Fair Condition, Fully Operational, Functional But Inefficient, Good Condition, In Storage, Needs Maintenance, New Condition, Outdated and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal conditions for 3D printing materials).

Whether you're just curious or building 3d printer conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify 3d printer conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Assurance in Manufacturing: The 3D printer conditions identifier can be integrated into manufacturing processes to ensure that the printers operate under optimal conditions. By identifying and flagging false images produced by printers, manufacturers can prevent defects, enhance product quality, and reduce waste.

- Predictive Maintenance: This function can be employed to monitor the operational state of 3D printers by analyzing print images for abnormalities. By detecting deviations early, businesses can schedule proactive maintenance, minimize downtime, and extend the lifespan of their equipment.

- Training and Development: The identifier can serve as a tool for training staff on proper 3D printing practices by highlighting what constitutes acceptable versus false outputs. This can improve the overall skill set of employees, leading to better management of printing equipment and higher quality outputs.

- Customer Support and Troubleshooting: Incorporating the identifier into customer support systems can help technicians quickly assess reports of 3D printing issues. By comparing submitted images against known faulty patterns, support teams can diagnose problems more efficiently and provide accurate solutions to customers.

- Automated Quality Control Systems: Integrating the identifier into automated quality control systems allows businesses to ensure continuous monitoring of printed parts. This leads to streamlined operations and reduces the human oversight needed in quality checks, resulting in quicker turnaround times and more consistent product outputs.

- Design Validation: The function can be utilized during the prototype phase to validate designs by comparing the output image to the intended design specifications. This capability enhances the iterative design process, allowing teams to refine their prototypes with greater accuracy before full-scale production.

- Regulatory Compliance: The 3D printer conditions identifier can help companies in regulated industries ensure compliance by documenting print processes and outputs. By automatically flagging false images, the system can support audits and maintain traceability, thereby mitigating risks associated with non-compliance.